Welding Course: Ultimate Guide to Becoming a Skilled Welder

Anúncios

Welding Course and Welder Training are pivotal to unlocking a lucrative career in the welding industry. This comprehensive guide covers everything from **basic techniques** to **career opportunities**, ensuring aspiring welders receive the knowledge and skills they need. Understanding different welding methods and investing in the right course can set you on a path to success. Dive in to learn more about this dynamic trade and what awaits you after mastering the art of welding.

1. Understanding the Basics of Welding

Learning welding basics is crucial for anyone aspiring to become a skilled welder. Start by familiarizing yourself with different metal types used in the industry, such as steel, aluminum, and stainless steel. Each metal has unique properties affecting how it’s welded.

Welding Processes

There are several welding methods to explore, including MIG, TIG, and stick welding. MIG welding is often recommended for beginners due to its ease and speed. On the other hand, TIG welding offers precision, making it ideal for intricate tasks.

Essential Concepts

Understanding concepts like arc stability, heat input, and joint preparation is vital. Heat input affects the strength and quality of the weld, while proper joint preparation ensures a secure bond between metal pieces.

Practicing these fundamentals in a controlled environment allows trainees to gain confidence and proficiency. Skills acquired during training are applicable to various industries, from automotive to construction.

2. Types of Welding Techniques Explained

Exploring different welding techniques is key to mastering the art of welding. MIG welding, or Metal Inert Gas welding, is popular for its ease and speed, often used in both industrial and personal projects. This technique involves feeding a wire continuously through a gun.

TIG Welding

TIG welding, or Tungsten Inert Gas welding, offers precision and is used for more delicate tasks. It requires a steady hand but produces high-quality welds. This technique uses a tungsten electrode and is often employed for materials like aluminum and stainless steel.

Stick Welding

Stick welding, or Shielded Metal Arc Welding (SMAW), is versatile and works well outdoors and on thick materials. It involves using a consumable electrode coated in flux to lay the weld, which is ideal for welding iron and steel.

Additional techniques such as plasma arc welding and flux-cored arc welding offer specialized options for specific conditions. Understanding these techniques allows welders to choose the best method for each project.

3. The Importance of Safety in Welding

Safety in welding cannot be overstated. Understanding the potential hazards and taking proactive measures is crucial for every welder. A primary concern is protection from burns, as welding sparks and hot metals pose significant risks. Wearing the right protective clothing, such as gloves and flame-resistant jackets, minimizes exposure.

Eye Protection

Using proper eye protection is vital. Welding arcs emit intense UV and infrared rays that can severely damage the eyes. A welding helmet equipped with the correct shade lens safeguards against these harmful effects.

Ventilation

Ensuring good ventilation in the welding area is essential to avoid inhaling toxic fumes and gases. Using fume extractors or working in open, well-ventilated spaces reduces these risks significantly.

Training in safe practices and staying updated with safety protocols helps in preventing accidents. Adhering to safety measures protects welders and maintains a healthy work environment.

4. Essential Tools and Equipment for Welders

Having the right tools and equipment is vital for any welder striving for precision and efficiency. A welding machine is the heart of any welding setup, available in various types, including MIG, TIG, and stick welders, each catering to different projects.

Protective Gear

Protective gear such as helmets, gloves, and safety glasses are essential to safeguard against sparks and intense light. A high-quality welding helmet with an auto-darkening feature can provide both protection and convenience.

Welding Tools

Basic welding tools like clamps, chipping hammers, and wire brushes ensure clean and secure welds. Clamps help hold metal pieces in place, while hammers and brushes remove slag and clean the work surface.

Measuring tools such as tape measures and squares are crucial for precise cuts and angles. Ensuring accuracy in measurements contributes to professional-quality work.

5. How to Choose the Right Welding Course

Finding the right welding course is pivotal to developing your skills and advancing your career. Start by considering the course curriculum. Ensure it covers essential aspects like welding techniques, safety, and tools. This will provide a comprehensive foundation in welding.

Accreditation

Choose a course that offers accreditation or a recognized certification. This not only enhances your credentials but also increases your job prospects in the welding industry.

Instructor Experience

Evaluate the instructors’ experience and background. Skilled and knowledgeable instructors can provide valuable insights and practical tips that enhance learning.

Consider the class format—whether it’s in-person or online—and how it fits your schedule and learning preferences. Hands-on practice is essential, so look for courses offering ample lab or workshop time.

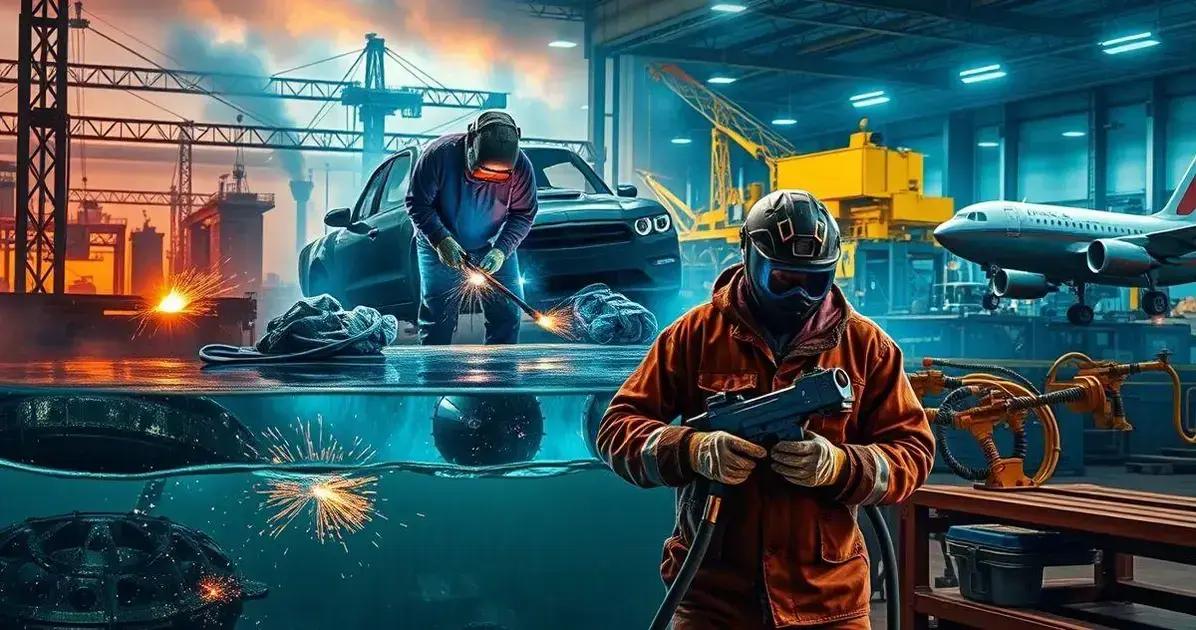

6. Career Opportunities After Completing Welder Training

Completing welding training opens doors to diverse and rewarding career paths. Certified welders are in demand in industries such as construction, manufacturing, and automotive. Entering the construction sector offers opportunities to work on infrastructure and building projects.

Manufacturing and Repair

Welding skills are essential in manufacturing, where welders are needed to fabricate and assemble metal products. In the automotive field, welders focus on vehicle repair and assembly, contributing to both safety and performance.

Specialized Fields

For those interested in specialized areas, underwater welding presents unique challenges and rewards. Alternatively, working in aerospace allows welders to engage with cutting-edge technologies and materials.

Attaining additional certifications in advanced techniques like TIG or MIG welding can enhance your expertise and increase earning potential. Continuous learning keeps welders competitive in a rapidly evolving industry.

Why Investing in Welding Training is a Smart Move

Embarking on a welding course offers more than just skill development; it opens a gateway to various exciting career opportunities. With a solid foundation in different welding techniques, professionals are well-equipped to enter fields like construction, manufacturing, and specialized areas.

Emphasizing safety and mastering essential tools ensure longevity in a physically demanding job. Choosing the right course that provides accredited certifications further enhances job prospects and career growth.

The demand for skilled welders continues to grow, driven by expanding industries and advanced technologies. By investing in comprehensive training, welders prepare for a future filled with innovation and opportunity, securing their place in a vital industry.

FAQ – Frequently Asked Questions About Welding Courses

What are the key benefits of taking a welding course?

A welding course provides essential skills, safety training, and certifications needed to pursue a career in various industries like construction and automotive.

How do I choose the right welding technique to learn?

Consider the types of projects you are interested in. For beginners, MIG welding is usually easiest. TIG welding offers precision for detailed work.

Why is safety training crucial in welding?

Safety training protects welders from hazards like burns and eye damage. It ensures a safe working environment and reduces the risk of accidents.

What tools are essential for a starting welder?

Essential tools include a welding machine, protective gear like helmets and gloves, clamps, chipping hammers, and measuring tools for accuracy.

What career opportunities are available after completing welder training?

Opportunities include working in construction, manufacturing, automotive repair, and specialized fields like underwater and aerospace welding.

Are welding certifications necessary for employment?

Yes, certifications can greatly enhance job prospects as they demonstrate expertise and adherence to industry standards.